SCADA

SCADA which stands for Supervisory Control and Data Acquisition is an industrial control system which utilizes software, hardware and communication infrastructure for process monitoring and control. SCADA system is utilized in the Industrial sector such as Oil and Gas, chemical, power, Refining, Food and beverage, pharmaceutical, energy, Telecommunication, etc.

Who need this training

The training is specifically for fresh graduates, Engineers, technologist and technicians, plant manager, supervisors as well as those with science background.

Course Objective

At the end of this Training our trainees will be able to:

- Demonstrate a sound understanding of how a SCADA system work

- Install, configure and program SCADA software

- Create a new SCADA application

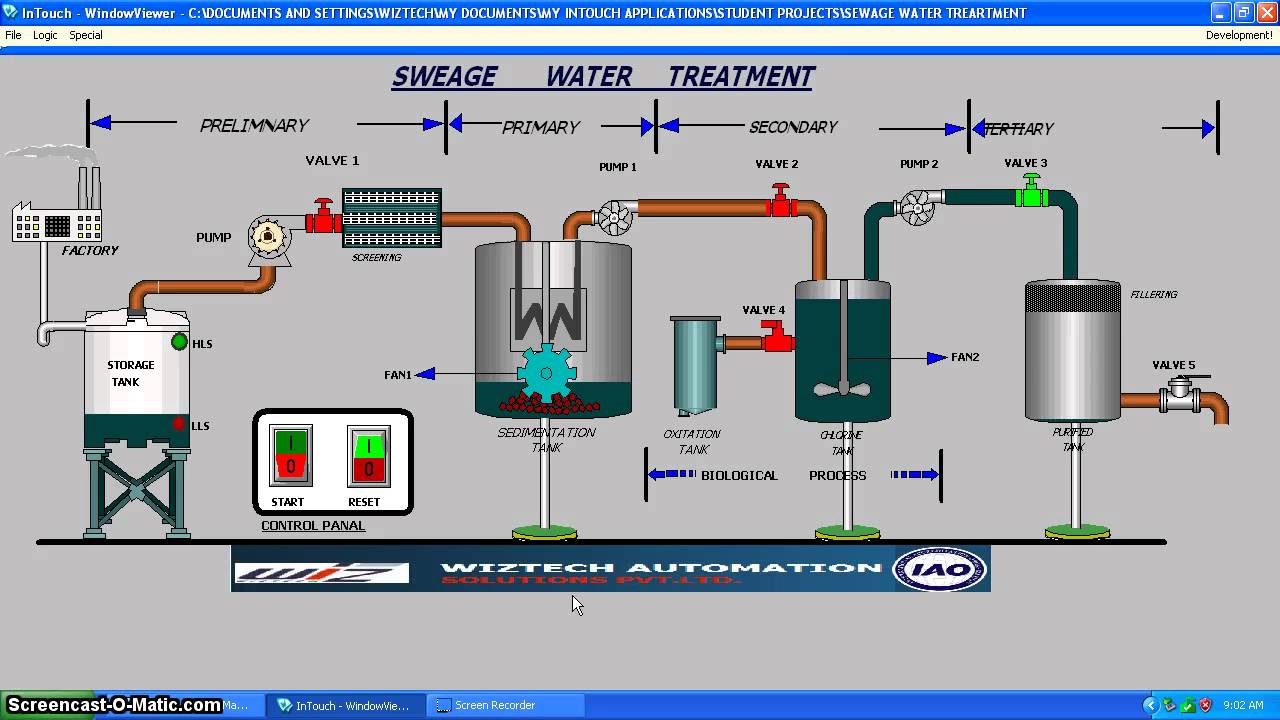

- Create tags, graphics, animation and dynamic display to mimic the actual controlled process

- Develop and write scripting program from control narratives

- Configure Alarms, Event and Trends.

- Demonstrate good understanding of OPC, DDE, DLL, etc as it relates to Driver/hardware interoperability set up

- Set up a simple SCADA system with its hardware and communication infrastructure

- Troubleshoot and diagnose software and communication issues in SCADA system

- Understand the security vulnerability of SCADA system and to make it more secured

Course Modules

Module I : Introduction to SCADA System

- SCADA System Definition, Evolution and application

- SCADA System Architecture

- SCADA System Comparism with other control System

- SCADA Software Overview

- Practice and Exercise

Module II: SCADA System Configuration and programming

- SCADA Software Installation and configuration

- Creating Application with SCADA

- Creating Database of Tags

- Creating & Editing graphic display with animation (filling, sizing, blinking, etc)

- SCADA scripting

- SCADA Communication with Hardware/software (concept of OLE, OPC, etc, VB, Excel, etc)

- Practice and Exercise

Module: III Trends, Alarm and Event

- Creating Alarm and Event

- Real Time and Historical Trends

- Real time project development with PLC interfacing

- Report generation

- Fault diagnostic and error handling

- Practice and Exercise

Module IV : SCADA Communication System

- SCADA Network Architecture

- ISO/OSI reference model and network protocol

- Field buses (Profibus, FF, Modbuses, DeviceNET, etc)

- Live set up of communication fieldbus network with PLCs, PCs, HMI and field instruments

- Troubleshooting communication error

- Sorting communication problems

- Practice and Exercise

Module V: SCADA System Security

- Overview of SCADA System vulnerability

- Access to different security level

- SCADA System Security control Methods

- Designing a security proof SCADA system

- Practice and Exercise

Available Software for SCADA Training

Wonderware

Factory Talk

RSview

IFIX 32

KingView

Citech

win cc

Duration: 20hrs/2weeks

click here to register for this course