Electrical control panel design, Installation and maintenance

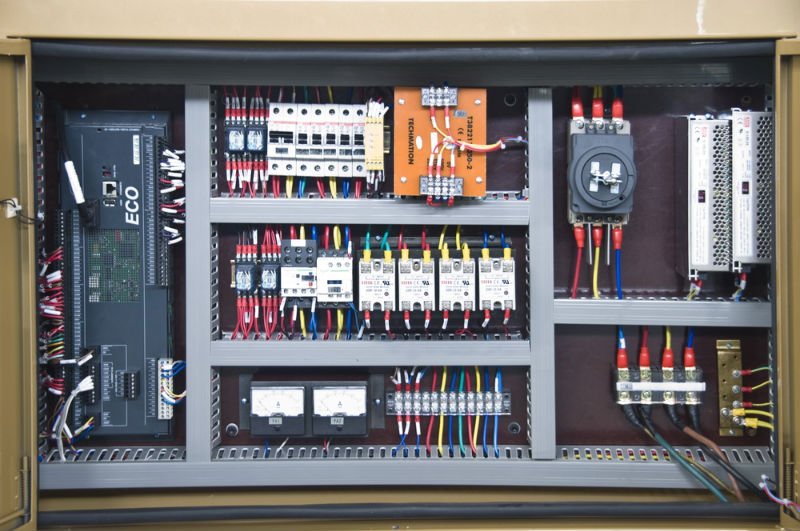

Electrical Control panel is an integral part of Electrical and Automatic control system used in the industries to control production process or machines. It may be built around Components such as Relay, Contactor, timer, counter, breaker or around programmable devices such as PLC, PAC, VFD, IED, etc. this is a very specialized field with a very few skilled personnel albeit very high industrial demand.

Who need this training

this training is meant for Engineers and technicians of Electrical/Electronic and computer background also, scientists with good electrical/electronic background. Both fresh graduate or experienced professional who may like to gain more skills

Course Objective

At the end of this Training our trainees will be able to:

- Demonstrate sound knowledge and understanding of various international Electrical standards such as IEC, NEMA, NPFA/NEC, UL, CSA

- Demonstrate good understanding of relay logic and how to apply it in solving real life control problem

- Wire up relays, timers, contactors, counters, breakers in conjunction with sensors to control electric motors, solenoid, robots, valves and other field instruments

- Troubleshoot and maintain control circuit

- Wire and configure AC and DC drive

- Wire and write PLC programs

- Demonstrate sound Knowledge of control panel design consideration such as knowing when best to use PLC based control panel or relay control panel

- Interface control panel to I/O device to match various load demand

- Upgrade a relay base control panel to PLC base control

Course module 1: Electrical Control Devices

- Operation Details of switch gear devices: Relay, Contactor, Starters, Timer, Counter, Breaker (MCB, MCCB, ACB, SF6, etc)

- switch gear Trip curves characteristics and its practical applications to load sizing.

- PLC and other Programmable devices

- AC and DC drives, soft starters operation details

- Electrical Symbol and wiring diagram

- Electrical schematic and relay logic

- Practice and exercise

Module 2: control panel design and installation

- Review of Panel design Standards: IEC, NEMA, NPFA/NEC, UL, CSA, etc.

- Develop wiring and schematic diagram from relay logic

- Design of control circuit using relay, contactor, starters, timer, counter, etc

- Detail wiring of control panel and interfacing with field devices

- Design and installation of industrial 3phase motor starter panel applying the IEC and NEC code

- Detailed component specification and sizing (very detailed interpretation of Motor nameplate)

- design and installation of Lighting system control panel, Automatic change over panel, generator protection panel, etc.

- Earthing and panel cabling-standard procedure

- Practice and exercise

Module 3: PLC based control panel

- Advantage of PLC base control Panel

- Detail wiring of a PLC control Panel

- PLC Programming, downloading/uploading PLC program

- Need for Industrial motor drives

- VFD wiring and configuration/parameterization

- Upgrading a relay control panel to PLC control panel

- Practice and exercise

Module 4: Control panel Maintenance

- Electrical test equipment

- Electrical troubleshooting procedure

- Common control panel faults and solution

- PLC and Drive troubleshooting

- Electrical motor troubleshooting and maintenance

- Practice and exercise