3D Printing Technology

THE 3D PRINTING REVOLUTION

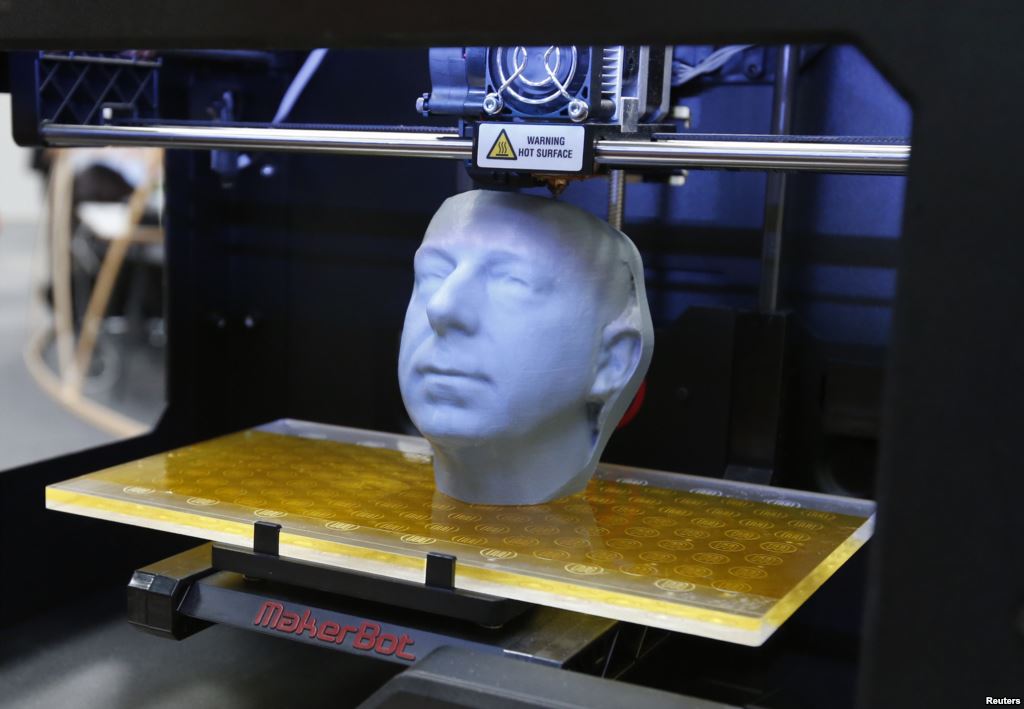

All around the world more and more people are employing 3D printing technologies in various ways. This trend has come to stay and keeps advancing every year as more additive manufacturing technologies come to light. Some call this the ‘Maker’ Revolution, while some refer to this as the 3rd Industrial Revolution, because of the disruptive effect it has on the global manufacturing landscape. It has made it possible for Makers to dream-up bigger and better products and at the same time achieve them faster and cheaper!

3D printing is being employed exhaustively in the Industrial Design field, where new and better products seem to be born every day, the Medical field employs 3d printing technologies exhaustively in development of prosthetics, dental fixtures and even 3d printed organs like livers, ears and skin.It’s employed extensively in the manufacture of custom jewelry as well as heavy-duty applications like 3D printed cars, jet engines and even buildings!

In summary 3D printing is extensively vast in its application-anywhere you see a new product now-a-days, almost certainly, 3D printing was involved. With all these advantages available to us, it is high time we rose up and took advantage of this technology and reap the substantial profits therein!

Here at ACECATECH, we elaborate in detail, and in a very practical way the beauty and especially the profitability of 3d printing. Making the student understand and explore available 3d printing technologies as well practice them, to ensure that the students hones 3d printing skills in a very practical way and profitable way! Let’s join the3rd Industrial Revolution, Let’s join the 3D Printing Revolution!

Our training is practical hands on with each participants carrying out a typical 3D project with the necessary software and a 3D printing machine.

Who needs this training?

- Product Developers

- 3D Printer Owners and Prospective owners

- Hobbyists and Enthusiasts

- Product Designers

- Science and Engineering Students

Prerequisite Knowledge

None necessary, but experience with any CAD software will be an advantage.

Course Objectives

At the end of this training, participants will be able to:

- Understand the usefulness of 3D printing and the unique role that it plays in modern Manufacturing.

- Understand the concept of Meshes and how to manipulate them suitably for 3d prints.

- Prepare a file for 3D printing, considering the best practices.

- Have a concrete understanding of how to use and troubleshoot an FDM printer.

- Design with 3D printing in mind using CAD software.

- Develop 3D scans and 3D print them.

- Understand and take advantage of the global Ecosystem of 3D printing resources.

COURSE MODULES

Module 1:Introduction to 3D Printing.

- The Wonders of Additive Manufacture.

- The Evolution of 3D Printing.

- The Uniqueness of 3D Printing.

Module 2:Understanding 3D Printing Technologies

- Stereolithography (SLA)

- Selective Laser Sintering or Laser Melting (SLS)

- Electron Beam Melting (EBM)

- Material Jetting (MJ)

- Fused-Deposition-Modelling (FDM)

- Electron Binder Jetting (BJ)

- Photopolymer Jetting (PolyJet)

Module 3:Understanding Meshes

- The things to consider while preparing a mesh file.

- The limitations of mesh files

- The concept of a ‘watertight’ mesh.

- How to repair a faulty mesh.

Module 4: FDM Printing Techniques

- The fundamental components of an FDM printer and some available varieties.

- Setting up your FDM printer

- How to properly Level a 3D printer.

- Understanding various 3d printing filament properties.

- How to properly set up the printing temperature for 3D printing job.

- How to prepare and maintain your printing surface.

- Understanding the concept of ‘slicing’.

- How to configure proper settings in a slicing engine to obtain high quality prints.

- Best practices to consider while 3d printing various types of objects.

- Understanding ‘g-codes’.

- 3D printing practicals.

Module 5:Exploring the 3D printing Ecosystem

- Exploring sources of design inspirations.

- The value of ‘making by sharing’.

- Understanding ‘Architecture’.

- How to learn from available designs.

- Taking advantage of diverse 3D printing resources.

Module 6: Designing for 3D Printing

- General design considerations for 3D printing

- Wall thickness

- Warping

- Level of detail

- Tolerance

- Considerations for designs involving;

- ‘Bridges’.

- Vertical axis holes

- ‘Overhangs’

- Corners

- Vertical pins

- Advanced tips to maximize the quality of 3D prints

- How to minimize the use of ‘supports’.

- How to prevent overheating and hence warping on parts with narrow points.

Module 7: 3D scanning Techniques

- The importance of 3d scanning

- Some available 3d scanning technologies and equipment.

- How to perform quality 3d scans using free software!

Course Duration: 3 weeks.

Register for this course here